Preserving the local harvest in tins! A factory in Paddock Wood

Tinned food which we may take for granted these days has an interesting history.

Napoleon is said to have declared “An army marches on its stomach” and during the first years of the Napoleonic Wars a large reward was offered to any inventor who devised a method of preserving large amounts of food needed for the troops. As a result during 1809 Frenchman Nicolas Appert developed a method of cooking food in sealed glass jars. Glass however was difficult to transport.

This was of course years before Louis Pasteur demonstrated the association of microbes with food decay (1860s) and when it became known that heat destroyed the offending creatures.

It was British inventors who developed the method of using sealed tin cans from (1810). The idea spread to America from where tins were exported and initially used by the Army and Navy. Mass production did not happen until early in the 20th century perhaps because effective can openers had not been invented. Soldiers were faced with cutting cans open with bayonets or smashing them with rocks which probably tried their patience. The Napoleonic wars ended in 1815 before the process could be perfected.

There was no canning industry in England before 1923. All was imported from abroad mainly America as mentioned above. However by 1935 there were 84 canning factories in Britain and one of those was in Paddock Wood. As many will know it was on the site where Waitrose now stands.

Across the country at that time more than 100 different varieties of food were canned. Fruit and vegetables as well as fish meat soup milk cream jams, mushrooms, apples, chickens, potatoes beans and tomatoes were preserved in this way.

A single factory in Wisbech bought products to the value of £1000 a week from local farmers which was a great boost to agriculture. At the time it was said 10,000 people were employed in the industry.

The factory at Paddock Wood was developed after the cattle market closed. The tall boiler chimney later became a local landmark in its later days. At the time the chimney was built there was a lift inside presumably for construction or maintenance. Bottling and canning was carried out and the factory carried on throughout the Second World War. Steam was used to boil the jam which was cooked in large tanks on the evening the fruit arrived. Sometimes farmers wet the fruit boxes so that they weighed heavier so it all had to be carefully checked.

The owner of the factory was Mr Stan Smedley. He would arrive in a Rolls Royce and his chauffeur would apparently look around and report anything he didn’t like to his employer like a ‘spy’. Mr Smedley owned other factories and the one in Wisbech was probably the first. Overalls worn by Paddock Wood staff had Wisbech as a motif. Others factories were in Evesham where plums were processed, Dundee known for raspberries and closer to home Barming where the famous peas were canned. In 1935 the firm was operating ten other factories.

For some time the factory manager in Paddock Wood was Mr Brunt, father of John Brunt VC. Before him it was Mr. Cockerel and perhaps another before but that is unknown to author.

A Paddock Wood resident, Eric, told how he served in the regular army and coincidently was sent to a battle school at Matfield. It was run by a strict captain of the Coldstream Guards. One day they were taken to a hill overlooking Paddock Wood where they looked down over Eric’s village with the factory chimney “standing like a sentinel”. One of the exercises was that one by one they had to call out as if they were directing fire to a certain point or target. Each man stood with the Captain so he could be corrected as necessary. When it was Eric’s turn he called out in a loud voice:

“Middle distance factory chimney! The boilerman’s name is Duke and he wear odd socks”

The shocked Captain shouted angrily “ What the ****!! are you on about” and the reply was “I live there sir”. There was a lot of laughter as a result, and the memory lived on for years.

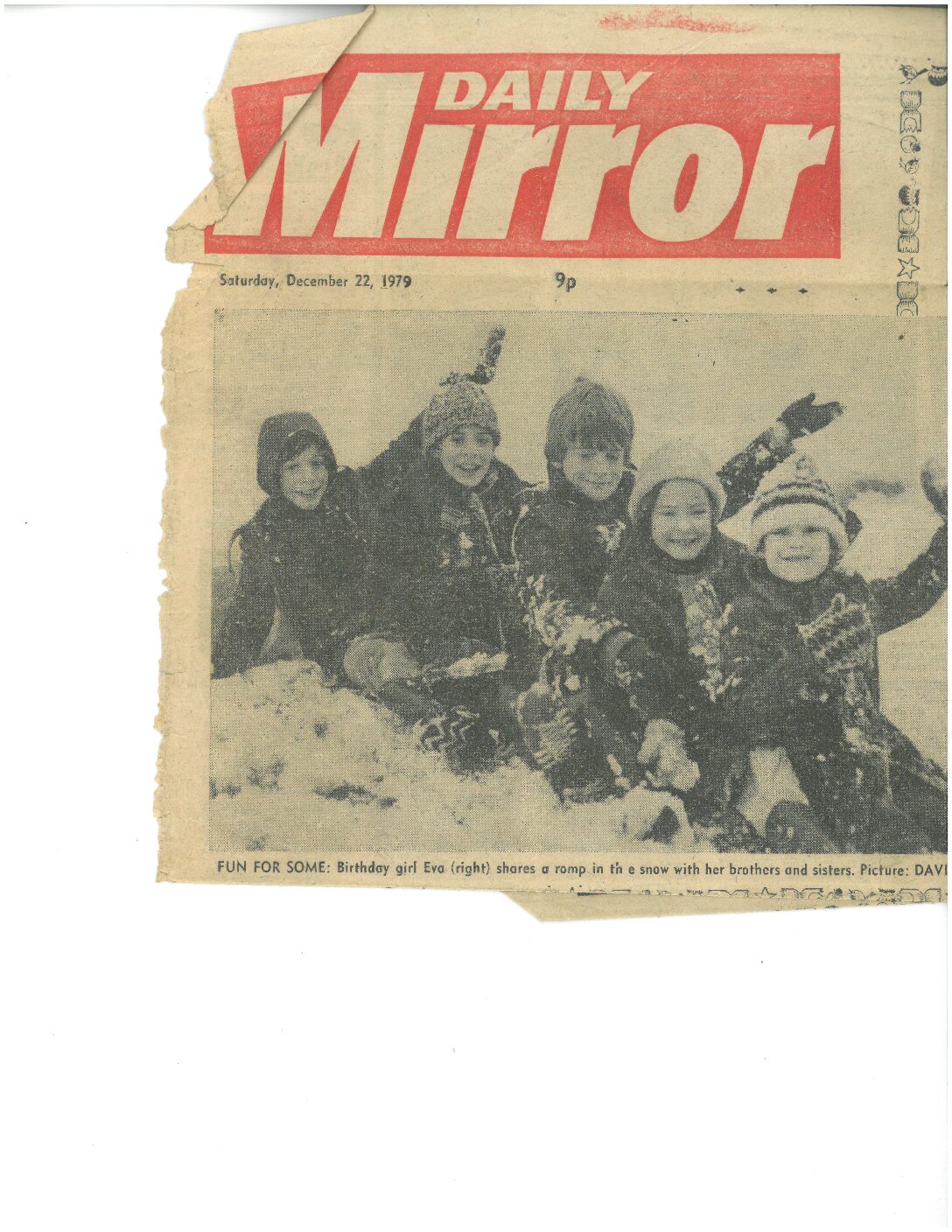

Pictures here are taken from the Weekly Illustrated (1935) and were taken at Paddock Wood. This was a record year for fruit and up to 200 people were busy in the factory where 300 tons of fruit was tinned for the winter. They worked day and night during all busy seasons and some of the girls would have to hurry for the last train to Tonbridge and surrounding areas. Some bicycled for long distances too. The factory was a valuable source of employment.

Cans whirled along on an endless belt to a syrup machine which dealt with hundreds in an hour. There was a laboratory where the syrup was prepared for the fruit and checked for the exact recipe to be used. Once sterilised the cans were lidded, cooked, cooled automatically, counted and labelled.

Before the canning process was possible fruit like plums that could not be eaten or bottled were thrown away. Blackberries were a useful source of pocket money for small boys and girls living near to the factories…if they could resist eating them.

Acknowledgements: Eric Knight, Paddock Wood Heritage, Weekly Illustrated Sept 21st 1935

Comments